The Comprehensive Basics of Sheet Metal Laser Cutting

The Comprehensive Basics of Sheet Metal Laser Cutting

Understanding sheet metal laser cutting technology can help you reduce material waste costs, improve product quality and make your production more efficient. This article is a complete guide with everything you need to know about laser cutting before starting your next manufacturing project.

What Is Sheet Metal Laser Cutting?

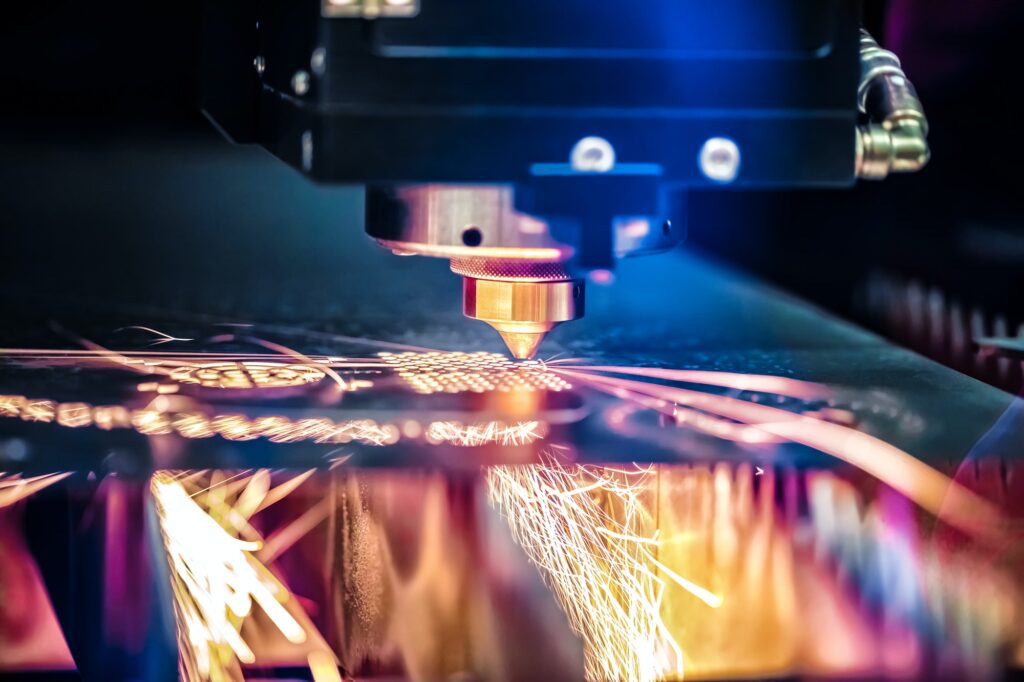

Sheet metal laser cutting is a primary industrial technique that uses a high-powered laser to precisely cut thin metal sheets.

This process employs computer numerical control (CNC) and optics to focus the laser, melting or vaporizing the metal to create intricate shapes with exceptional accuracy.

The laser melts or vaporizes the metal, creating intricate shapes and patterns with clean edges and minimal waste.

Known for its accuracy and speed, laser cutting is widely used in industries like automotive, aerospace, and electronics for effective material modification and component fabrication.

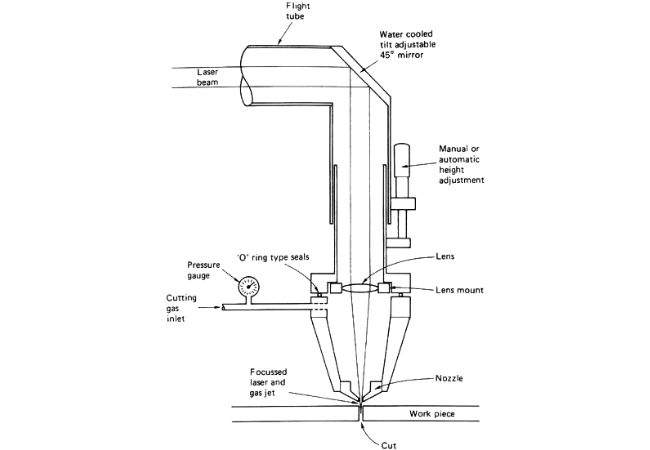

The Sheet Metal Laser Cutting Process

The sheet metal laser cutting process starts with creating a digital design, which you then upload into the laser cutting machine’s control system. Next, the metal sheet is carefully positioned and secured on the cutting bed.

The machine uses a high-powered laser beam, guided by CNC technology, to cut through the metal by melting, burning, or vaporizing it along the design path.

Assist gases are used to clear away molten material and improve the cut quality. The process is closely monitored and adjusted as needed.

Once cutting is complete, the parts are removed and may go through additional finishing and quality checks.

The methods for laser cutting sheet metal

1.Laser Beam Fusion Cutting

The laser beam fusion cutting process uses an inert gas, typically nitrogen or argon, to continuously vaporize and remove molten material from the cutting area. This inert gas prevents oxidation at the cutting edge without interfering with the process.

Fusion cutting is ideal for flat, thin sheets of aluminum alloys and stainless steel, especially when high aesthetic quality and minimal finishing are required.

This method ensures clean cuts with fewer post-processing needs, making it suitable for applications that demand both precision and visual appeal.

2.Laser Beam Sublimation Cutting

Laser beam sublimation cutting uses a laser to evaporate material directly, changing it from solid to gas without melting. Inert gases such as nitrogen, helium, or argon are used to blow away the vapor and keep the cutting edges free of oxidants.

Although this process is slower compared to other methods, it produces high-quality edges with excellent precision.

Sublimation cutting is particularly well-suited for organic materials like wood, leather, and textiles.

3.Laser Beam Flame Cutting

Laser beam flame cutting integrates laser technology with oxygen to cut materials efficiently.

In this process, a high-energy laser beam melts the workpiece while oxygen gas is introduced to ignite a combustion reaction with the molten material. This exothermic reaction provides additional energy, enhancing the cutting efficiency.

Flame cutting, which also uses oxygen to expel molten material, is ideal for mild steel, other metals, and fusible materials like ceramics.

The combination of laser heating and oxygen-induced combustion results in precise cuts with increased energy input.

What Is Sheet Metal Laser Cutting?

- Let’s explore some of the advantages of using laser cutting to cut metal:

- Precision and Accuracy: Achieves tolerances as tight as ±0.1 mm, ensuring minimal deviations from design specifications.

- Minimal Material Waste: Kerf width of 0.1 to 0.2 mm results in up to 20% less material waste compared to other method.

- Versatility: Capable of cutting a wide range of materials, with fiber lasers handling up to 25 mm thick and CO2 lasers up to 50 mm thick.

- Speed: Reaches cutting speeds of up to 20 meters per minute, enhancing turnaround times and productivity.

- High-Quality Cuts: Provides edges with a surface roughness around Ra 0.5 µm, minimizing the need for further finishing.

- Reduced Need for Tooling: No physical tools or dies are required, cutting setup times and costs by up to 50%.

- Automation: Fully compatible with CNC systems, increasing production rates by up to 30% through automation.

- Flexibility: Adapts quickly to design changes via software, supporting rapid prototyping and short-run production.

- Minimal Heat Affected Zone (HAZ): Reduces warping and distortion with a significantly smaller HAZ compared to other cutting methods.

Disadvantages Of Laser Cutting Sheet Metal

- Initial Cost: Laser cutting machines can cost over $100,000, making them less accessible for small businesses and startups.These machines can use up to 20 kW of power during operation.Annual maintenance for laser cutting systems ranges from $5,000 to $10,000, covering parts like lenses and mirrors.

- Material Limitations: Laser cutting is less effective on reflective materials like copper and brass, potentially losing up to 30% of beam efficiency.

- Thickness Restrictions: Cutting materials thicker than 25 mm can be challenging and may require specialized equipment.

- Material Waste: Even with high precision, laser cutting can produce up to 10% more material waste if part nesting is not optimized.

Ways to Minimize Sheet Metal Waste in Laser Cutting

Reducing metal waste in laser cutting offers both economic and environmental advantages.

Efficient planning maximizes material utilization, helping control manufacturing costs while minimizing scrap production. This not only saves money on materials and waste transport but also cuts down time spent cutting.

Additionally, less waste means fewer emissions from machines and less metal ending up in landfills. By reducing offcuts, businesses can even explore recycling scrap metal for extra income.

These reasons make it clear why minimizing sheet metal waste is essential.

Here is how you can reduce material waste during laser cutting:

Optimize Nesting of Shapes: Arrange pieces closely together to fit the maximum number of parts. For complex designs, consider using automated nesting tools to efficiently organize shapes, reducing material waste and cost.

Use Shared Cutting Lines: Ensure shapes share cutting edges where possible to minimize space between them. This reduces material waste, shortens cutting time, and lowers machine running costs.

Simplify Curves and Components: Eliminate unnecessary curves and details to speed up the cutting process. Adjust cutting positions for efficiency, and account for complex designs in project costs.

While offcuts are inevitable in most sheet metal fabrication processes, you can still reduce waste in laser cutting by reusing them.

Offcuts can be repurposed for smaller, intricate parts or test cuts, helping to maximize material usage.

Proper storage and organization of offcuts are key to ensuring they’re readily available for future laser-cutting projects, making the process more efficient and sustainable.

When laser cutting metal, what are the important factors to consider?

The quality of your laser-cut parts heavily relies on both the condition of your laser cutting equipment and the precision of your cutting parameters.

Regular maintenance of the laser cutter helps minimize process irregularities and ensures consistent performance.

To achieve top-notch results, it’s essential to carefully adjust cutting parameters, such as power, speed, and assist gases, based on the material and design requirements.

When laser cutting metal, consider the following key factors to ensure optimal results:

Material Type and Thickness: Different metals and their thicknesses affect the required power, cutting speed, and gas pressures. Understanding how each material responds to the laser is crucial for achieving high-quality cuts.

Laser Power and Type: The choice between CO2 and fiber lasers, along with the appropriate power level, impacts cutting speed, quality, and material thickness capabilities. Higher power lasers are generally needed for thicker materials.

Cutting Speeds: While faster cutting speeds can boost productivity, they may also introduce more heat, which can affect edge quality and smoothness. Balance speed with the need for precision and minimal post-processing.

Assist Gas: Different assist gases, such as oxygen or nitrogen, influence cut quality, speed, and heat management. Proper gas selection helps in removing melted material and maintaining clean cuts.

Design Complexity: Intricate designs require careful planning of cutting paths and may necessitate secondary operations like bending or deburring. Complex designs can impact cutting time and precision.

Common Mistakes to Avoid:

Ignoring Kerf: Failing to account for the kerf (the width of the cut) can lead to inaccuracies in the finished product. Ensure your design includes this adjustment.

Neglecting Parameter Testing: Always test and adjust laser settings (power, speed, and assist gas) when switching between different materials or thicknesses to ensure optimal performance.

Overlooking Machine Maintenance: Regular maintenance, such as cleaning lenses and checking alignment, is essential for maintaining cut quality and prolonging machine life.

By addressing these factors and avoiding common mistakes, you can enhance the quality and efficiency of your metal laser cutting processes.

Conclusion

Are you in search of a reliable company for top-notch laser cutting services? Look no further than YISHANG.

We specialize in sheet metal fabrication for both rapid prototyping and custom production, ensuring exceptional quality and precision. With our cost-effective and on-demand solutions, we meet your needs efficiently and reliably.

Choose YISHANG for your laser cutting projects and experience unmatched service and results.

Contact us now if you need sheet metal laser cutting.