Comprehensive Guide to Sheet Metal Stamping

Comprehensive Guide to Sheet Metal Stamping

Sheet metal stamping is a critical manufacturing process that offers high precision, efficiency, and cost-effectiveness for large-scale production.

To master Sheet metal stamping and become an expert, make sure to read this guide in its entirety.

What is Sheet Metal Stamping?

Sheet metal stamping is a manufacturing process used to shape flat sheets of metal into specific forms by applying pressure through a stamping press.

The process typically involves a die and a punch, where the sheet metal is placed between them and then shaped by applying force.

Stamping is widely used in industries like automotive, electronics, aerospace, and appliances to produce parts such as brackets, enclosures, and body panels.

Basic techniques of Sheet Metal Stamping

In sheet metal stamping processes are included a wide variety of associated operations:

- Blanking:A flat piece of metal, called a blank, is cut from a larger sheet to the desired size. This is typically the first step in the stamping process and provides the raw material for further operations.

- Bending:The metal may be bent to specific angles or curved forms by applying additional pressure.Bending is commonly used for creating brackets, enclosures, and other angular parts.

- Coining:Coining is a precise bending method in which the metal workpiece is placed between a die and a punch or press. During coining, the punch exerts pressure on the metal, causing it to conform to the die’s shape with high accuracy. This technique ensures consistent, repeatable bends and effectively eliminates internal stresses, preventing any spring-back effects.

- Piercing:Piercing is a process of creating holes or cut-outs in the sheet metal. This is used for applications like vents, mounting holes, and fastener locations.

- Punching:CNC punching is a key method for producing sheet metal blanks efficiently. This process excels in scenarios where numerous identical features or large quantities of parts are required, making it a faster alternative for high-volume metal fabrications.

- Drawing:Drawing involves pulling the sheet metal into a die to create deep, hollow shapes like cups or cylinders. Deep drawing is essential in producing components such as metal cans or automotive parts.

- Embossing:Metal embossing involves creating a raised design on metal sheets by pressing them with an embossing tool or stylus. The process works by pushing the metal against a die to form a textured pattern on the reverse side. To achieve a smooth, polished finish or to apply pigments, the metal sheet is placed on a rubber or foam pad, which supports the metal and ensures a clean, even impression.

- Flanging:Flanging in sheet metal stamping involves bending the edge of a metal sheet at a specific angle to create a raised or protruding edge for assembly or reinforcement.

- Forming:The blank is positioned in a die, and a punch applies force to shape it into the desired form.

- Trimming:Any excess material is trimmed away from the finished part for precision and quality.

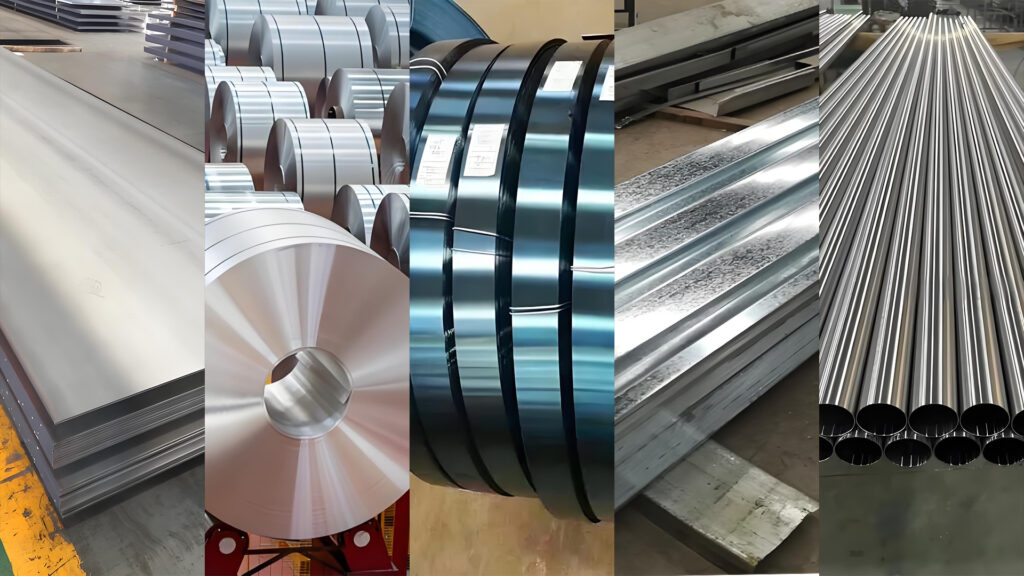

Materials Suitable for Sheet Metal Stamping

needs. If your preferred material isn’t listed below, please reach out to us to discuss your specific requirements and find the perfect solution for your project.

- Carbon Steel

- Cold Rolled Steel

- Hot Rolled Steel

- Galvanized Steel

- Stainless Steel

- Aluminum.

- Brass

Our stamping materials are available with various post-processing options, including bead blasting, powder coating, chem film, anodizing, and plating in gold, silver, or electroless nickel.

For detailed information on our finishing services, please visit our main sheet metal fabrication page.

Types of Stamping

We provide a comprehensive range of stamping techniques,including progressive die stamping,fourslide stamping,deep draw stamping,transfer die stamping,and additional methods.

This variety allows us to select the most efficient and effective approach for producing your products.

1.Progressive die stamping

Progressive die stamping efficiently produces complex metal parts by using multiple sequential dies. This method allows for the continuous feeding of metal strips through various stamping stations, each performing different operations like cutting and bending.

Unlike transfer die stamping, which moves parts along a conveyor, progressive die stamping keeps the workpiece on a strip, ensuring precision and efficiency in large-scale manufacturing.

2.Fourslide stamping

Fourslide stamping, also known as multi-slide stamping, uses four horizontal slides to simultaneously perform multiple bends and cuts, offering superior design flexibility.

Unlike traditional stamping, which typically uses a single vertical die, fourslide stamping can create intricate parts with complex geometries more efficiently.

Its versatility and speed make it ideal for small, detailed components in industries like electronics and aerospace.

3.Transfer Die Stamping

Transfer die stamping, like progressive stamping, uses multiple dies but transfers the part via mechanical systems, such as conveyors, rather than feeding it continuously.

This method is ideal for larger or more complex parts needing additional operations, offering precise control and flexibility compared to continuous processes.

4.Deep Draw Stamping

Deep draw stamping involves pulling a sheet metal blank into a die using a punch, creating deep, rigid parts like cylinders or boxes. Unlike shallow stamping, deep drawing allows for deeper cavities and is more material-efficient compared to turning processes.

This method is ideal for parts requiring significant depth and multiple diameters.

5.Fine Blanking

Fine blanking is a precision stamping process that delivers high-quality, burr-free parts with exceptional flatness and accuracy. It involves clamping, blanking, and ejecting in a single, cold extrusion step, using higher pressures than conventional stamping.

This results in smoother edges and fewer fractures, distinguishing it from other methods.

6.Short Run Stamping

Short run stamping is ideal for prototypes or small projects, with minimal upfront tooling costs. Using custom tooling and die inserts, manufacturers can bend, punch, or drill parts without expensive tooling setups. While per-piece costs may be higher, the overall savings and fast turnaround make it cost-effective for smaller runs compared to high-volume stamping processes.

Advantages of Sheet Metal Stamping

High Efficiency:Stamping is ideal for mass production, where thousands or millions of identical parts can be produced quickly and consistently.

Cost-Effectiveness:Once the tooling is set up, the per-unit cost of stamped parts decreases significantly, making it cost-effective for large production runs.

Precision and Accuracy:With the use of high-precision dies and presses, stamping can achieve tight tolerances, ensuring consistent part quality.

Sheet Metal Stamping by Industry

- Automotive Industry:Sheet metal stamping is widely used to produce vehicle body panels, engine components, and brackets. Its precision and ability to handle high volumes make it essential for automotive manufacturing.

- Electronics Industry:This process creates small, intricate parts like connectors, terminals, and frames used in electronic devices. Stamping ensures high accuracy and consistency for mass-produced components.

- Aerospace Industry:Aerospace relies on metal stamping for lightweight, durable parts like fuselage sections and brackets. Stamping ensures precision and the strength needed to meet aerospace safety standards.

- Medical Industry:Metal stamping is vital for producing medical devices, implants, and surgical instruments. The process meets stringent regulatory requirements, ensuring high precision and clean production.

- Consumer Goods:Household items like appliances, kitchen utensils, and electronics rely on sheet metal stamping for mass production. Stamping ensures affordability and quality for everyday products.

- Industrial Equipment:Stamping is used to create durable parts for HVAC systems, machinery, and tools. Its precision and strength make it ideal for industrial applications where reliability is critical.

- Renewable Energy:Stamped metal components are key in solar panels, wind turbines, and energy storage systems. Stamping allows for the efficient production of durable and sustainable energy solutions.