- huxanhe@zsyishang.com

- +8613590721715

- HOME

- WHY YISHANG

Capabilities

Design Support

- PRODUCTS

- GALLERY

- SUPPORT

- CONTACT US

An electrical control box metal enclosure is a protective casing made from metal, designed to house electrical components and control systems. It provides security against environmental factors like dust, moisture, and mechanical damage, ensuring the safe operation of electrical equipment in industrial and commercial settings.

YiShang’s Electrical Control Box Metal Enclosures are designed to offer exceptional protection and durability for electrical components. Crafted with precision and high-quality materials, our enclosures are perfect for housing sensitive electrical equipment in various industrial and commercial applications.

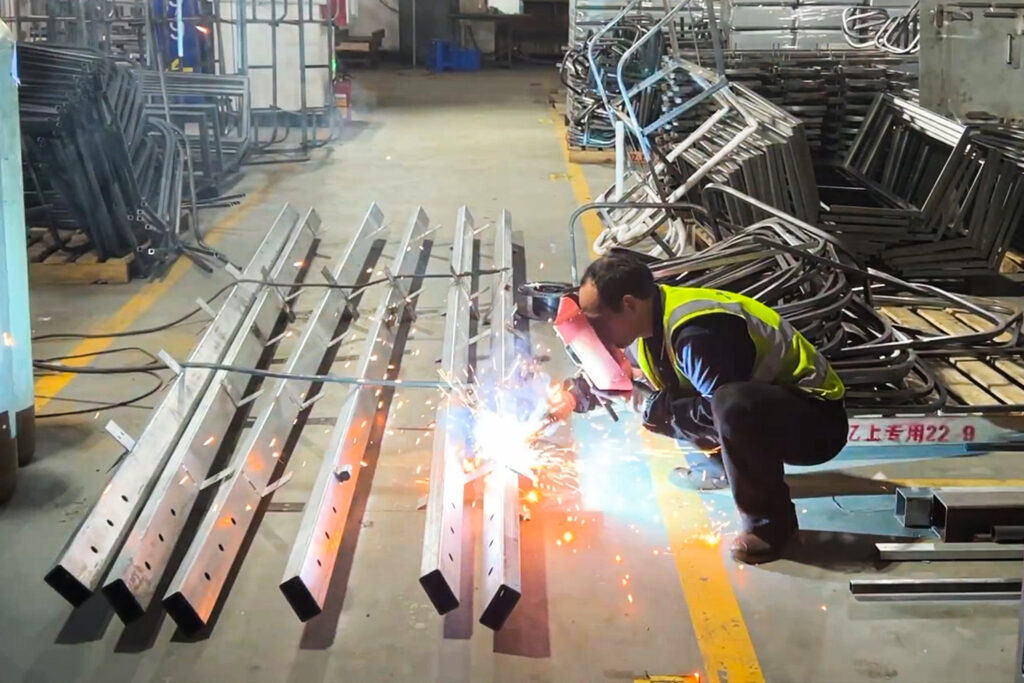

At YiShang, we follow a detailed and precise manufacturing process to ensure that each Electrical Control Box Metal Enclosure meets the highest quality standards. Below is an overview of our production process:

This thorough process ensures that each Electrical Control Box Metal Enclosure from YiShang meets the highest standards of quality, durability, and functionality. Feel free to reach out if you need any specific details added to this flow!

Yishang offers a wide range of standard sheet metal box fabrication materials. We specialize in stainless steel, mild steel, galvanized steel, cold rolled steel, aluminum, copper, brass and more.

Each of these metals is known for its ability to operate effectively in a wide range of industrial applications. Material selection is particularly compatible with sheet metal fabrication techniques. Our knowledgeable staff will discuss these and other material options with you.

Your experienced designers have an in-depth understanding of your customer’s needs and help you optimize a solution that fits your needs with China pricing. We can provide 3D design drawings within 2 hours after you provide us with your design ideas.

We have been specializing in one-stop solutions and customized services for sheet metal fabrication for over 26 years, choose YISHANG for your 1-hour instant quote and 2-hour rapid prototyping service, contact us today!

Yishang manufactures high quality metal enclosures that can withstand the rigors of the semiconductor industry. These housings are used to protect electronic devices from automotive wear and tear, and KDM can mass produce boxes for your business.

The importance of sheet metal boxes in the electronics industry is immeasurable. They offer a variety of advantages including emission reduction, electrical conductivity and more. These boxes are resistant to harsh industrial environments.

Yishang specializes in manufacturing sheet metal cabinets for communication systems. These cabinets have excellent features such as waterproofing, fireproofing, Nema/UL testing, and can be mounted on walls, towers or poles. Other models are freestanding.

Boxes For Aerospace Applications Come With A Range Of Material Selections. We Treat Titanium, Aluminum, Carbon Steel, Or Stainless Steel. The Dimensions Of The Pieces Are Precise And Long-Lasting. Designed To Meet The Industry’S Stringent Requirements.

Metal boxes are manufactured to build energy production systems, reducing production costs while improving quality and consistency, using copper, steel and other materials to make containers for the social energy sector.

If you have any questions or need a quote, please send us a message. One of our specialists will get back to you within 24 hours and help you select the correct valve for your needs.

All of our products are available for sampling