Sheet Metal Welding: A Comprehensive Guide for Custom Metal Fabrication

Sheet Metal Welding: A Comprehensive Guide for Custom Metal Fabrication

Sheet Metal Welding Introduce

Sheet Metal WWelding is one of the most critical processes in sheet metal fabrication, used to join metal sheets and create strong, durable components.

In this guide, we'll explore the fundamentals of sheet metal welding, its techniques, and the best practices for ensuring high-quality results.

What Is Sheet Metal Welding?

Sheet metal welding is the process of joining thin metal sheets using heat, pressure, or both to create strong, durable bonds. Unlike thicker metals, welding sheet metal requires precise control to prevent warping and maintain material integrity. This technique often involves a filler material, which melts and fills gaps between metal pieces to form a seamless, strong connection. Used in industries like automotive, aerospace, and construction, sheet metal welding enables the creation of complex, lightweight, and robust assemblies critical for both structural and aesthetic purposes.

Methods Of Welding Sheet Metal

Now, let’s take a comprehensive look at some methods for melding metal sheets.

1.MIG Welding

MIG welding, or Gas Metal Arc Welding (GMAW), is a versatile and efficient welding process using a continuous wire electrode and a shielding gas to prevent oxidation.

Ideal for joining metals like steel, aluminum, and stainless steel, MIG welding creates strong, high-quality welds quickly. Its speed and adaptability make it perfect for larger and thicker sheet metals, commonly used in industries like automotive and construction.

While it offers excellent weld strength, controlling the weld puddle can be challenging, leading to imprecise results without proper skill.

2.TIG Welding

TIG welding, or Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to produce precise, high-quality welds.

Unlike MIG welding, the electrode doesn’t melt; instead, filler metal is manually fed into the weld. This method offers superior control, making it ideal for thin metals and projects requiring clean, strong welds with minimal distortion.

Although slower and more skill-intensive than MIG, TIG welding excels in applications like aerospace, automotive, and custom fabrication due to its precision and reduced heat output.

3.Stick Welding

Stick welding, also known as Shielded Metal Arc Welding (SMAW), uses a consumable electrode coated in flux. As the flux burns, it creates a gas shield that protects the weld from contamination, eliminating the need for external shielding gas.

Unlike TIG or MIG, stick welding is versatile and works well on rough, dirty, or rusty materials, making it ideal for outdoor and heavy-duty applications like construction and shipbuilding.

Its portability and ability to handle tough metals like iron and steel set it apart from other welding methods.

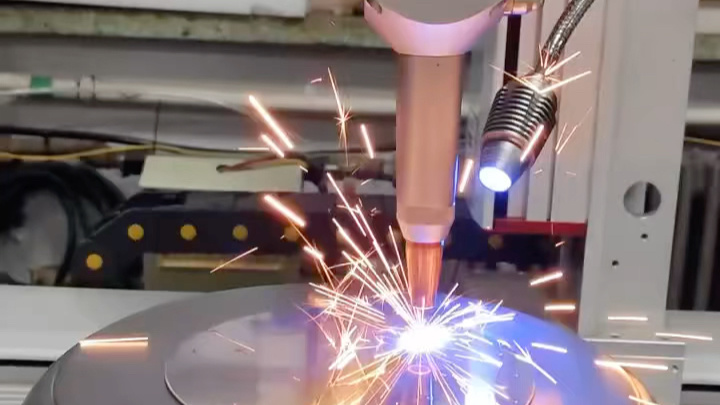

4.Plasma Arc Welding

Plasma Arc Welding (PAW) is similar to TIG welding but uses a highly concentrated plasma arc, allowing for deep penetration and precise welds.

Unlike other methods, PAW utilizes pressurized gas to form a hot plasma, melting metals together with minimal heat-affected zones. This precision makes PAW ideal for industries like aerospace and marine.

Unlike TIG, it operates faster and does not require filler materials, producing high-quality welds with less finishing. PAW’s ability to focus energy in small areas sets it apart from other welding techniques.

5.Laser welding

Laser welding uses a concentrated laser beam to melt and fuse materials with high precision, allowing for deep, narrow welds and minimal distortion.

Laser welding includes two primary types: cosmetic (or conduction) and keyhole. The cosmetic weld uses a defocused laser to create a smooth, wide seam. In contrast, the keyhole weld penetrates through the first layer into the second, forming a strong joint as the molten material solidifies. Keyhole welding is chosen for applications requiring a secure seal rather than a smooth appearance.

Unlike TIG and MIG welding, it requires no filler material, making it ideal for smaller parts and tight gaps under .005”.

This method is fast, offering speeds up to 80” per minute, and is commonly used in industries like medical devices, electronics, and automotive manufacturing, where accuracy and aesthetics are critical. Its high energy density and minimal heat input set it apart from traditional welding methods.

6.Gas Welding

Gas welding, also known as oxy-fuel welding, uses a torch to mix gases like oxygen and acetylene to create a high-temperature flame that melts metals for joining.

This method is highly portable and does not require electricity, making it economical and versatile for both ferrous and non-ferrous metals.

Unlike more modern techniques, gas welding can be slower and less precise but is valued for its simplicity and effectiveness in tasks like pipe welding and repairs.

It excels in applications where gradual heating and cooling are needed but falls short of the high temperatures achievable with methods like arc welding.

7.Spot welding

Spot welding(or resistance welding)joins metal sheets by applying pressure and localized heat through copper electrodes. This method generates intense heat through electrical resistance, creating small weld pools at specific points.

Unlike MIG or TIG welding, which involve continuous welding, spot welding is ideal for high-volume production with minimal warping.

It’s particularly effective in automotive manufacturing, offering robust, permanent joints without the need for filler materials.

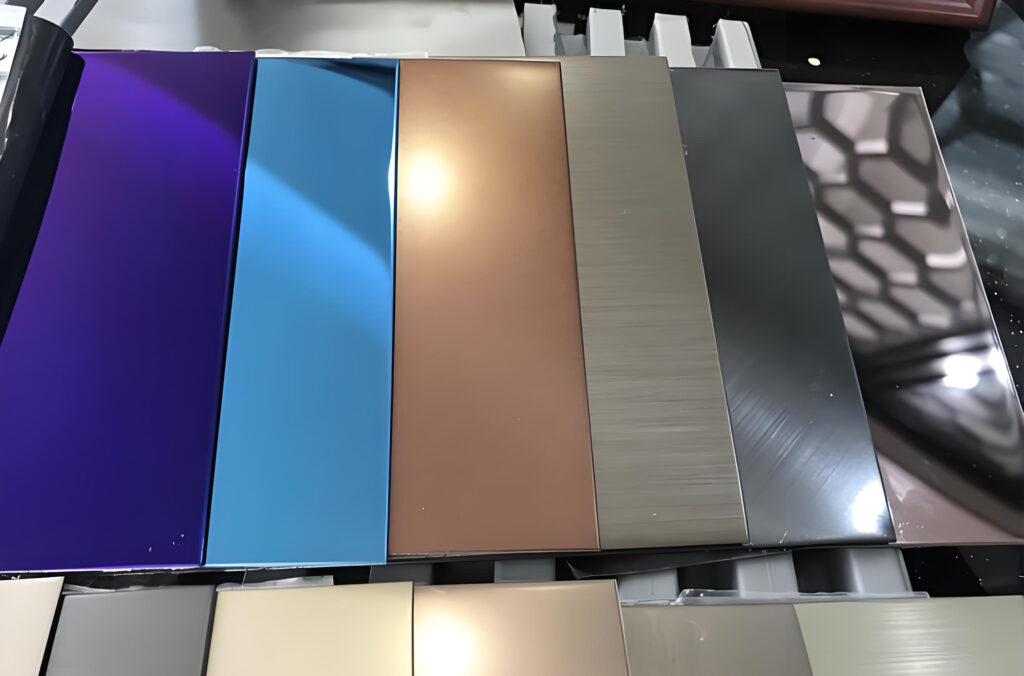

Consider Surface When Choosing Sheet Metal Welding Methods

When selecting a sheet metal welding method, surface considerations play a crucial role. Key factors include:

Surface Cleanliness: Methods like TIG welding require clean surfaces for optimal weld quality, while MIG welding is more forgiving of surface impurities.

Surface Coating: Coated metals may need specialized processes like laser welding to avoid damage to the coating, ensuring the final product retains its finish.

Material Thickness: Thinner materials are more prone to distortion, so low-heat methods like resistance welding are preferable to minimize surface warping.

Oxidation Resistance: Some metals are prone to oxidation during welding, requiring protective gases like argon in processes such as TIG or MIG welding to preserve the surface quality.

Considering surface characteristics helps in selecting the most appropriate welding method for durable and high-quality results.

Sheet Metal Welding Tips You Should Know

Welding sheet metal requires precision and proper techniques to achieve strong, clean welds. Here are some essential tips to ensure high-quality results:

Choose the Right Welding Process

Each metal type requires a specific welding process. MIG is faster and suitable for thick materials, while TIG ensures precision and clean welds for thinner metals like aluminum.

Choose the Right Welding Process

Each metal type requires a specific welding process. MIG is faster and suitable for thick materials, while TIG ensures precision and clean welds for thinner metals like aluminum.

Select the Proper Filler Metal

The filler metal should match the base metal in strength and composition. A thinner filler is preferred for sheet metal to reduce the risk of overheating and distortion.

Control the Heat

Managing heat is critical for preventing distortion. Skip or tack welding minimizes overheating, while using backing bars and pulse techniques helps dissipate excess

Ensure Surface Cleanliness

Contaminants like oil or rust can weaken weld quality. Clean the workpiece of oils, oxides, and debris before welding to avoid defects like porosity or lack of fusion in your weld.

Employ Proper Fixturing

Clamps, jigs, and backing bars stabilize the metal during welding. This reduces movement, ensures alignment, and aids in even heat distribution for consistent weld quality.

Choose a Small Wire Diameter

When using MIG welding, select a small wire diameter for better control and to minimize spatter. Smaller wires also reduce heat input, improving weld quality on thinner sheet metal.

Test and Adjust Settings

Always test your welding technique on scrap metal before starting production. Adjust heat, wire speed, and shielding gas for the best results, ensuring you minimize defects.

By following these tips, you’ll improve your sheet metal welding outcomes, ensuring strong, durable welds suitable for various applications.

How do youWhat is the difference between spot welding and MIG welding?

Spot welding uses localized pressure and heat for quick, precise welds, while MIG welding uses a wire feed and is ideal for larger seams and continuous welding.

prevent warping during welding?

Techniques like spot welding, stitch welding, and using proper heat control help minimize warping in thin sheet metals.

Conclusion

Looking for expert sheet metal welding services? Whether you’re tackling a DIY project or need professional help, YISHANG offers top-notch solutions.

From precise laser cutting to custom welding, our skilled team is here to bring your vision to life.

Choose YISHANG for quality, reliability, and exceptional results.